CORITEC 650i Loader, 5-axis dental miling machine

Description

PREMIUM machine for PREMIUM requirements.

High end quality with future-oriented technology

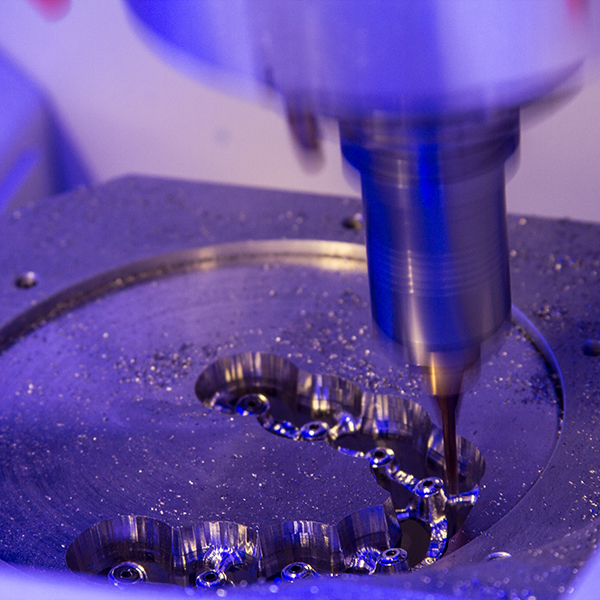

We developed the CORiTEC 650i and CORiTEC 650i Loader machine systems for the PREMIUM machine segment and for PREMIUM requirements. The systems are offered at a very attractive price and are equipped with high-quality industrial milling technologies, such as granite structure, linear drives in the linear axes, torque motors in the rotary axes, as well as digital absolute length measuring systems and powerful main spindles. The machine concept impresses with its precise, vibration-free and dynamic motion sequences in the demanding and complex metal working processes.

All other relevant materials can also be milled or ground at high quality with this system (wet and/or dry machining). The CORiTEC 650i loader includes a fully integrated automatic 16-fold blank changer. This lets you to operate the machine system at full capacity around the clock without supervision, while maintaining consistent high precision. Thus, the machine system is ideally suited for large labs and milling centers, where these high quality standards and large quantities are required.

Technical Highlights

- Solid axis structure made of polished natural granite for highly dynamic 5-axis simultaneous machining and for highly precise milling results

- Absolute, high-resolution measuring systems on all axes

- High-frequency spindle with up to 50,000 rpm and 2.3 kW with HSK 25 tool holder

- 32-fold fully automatic tool changer

- 16-fold fully automatic blank changer

- Integrated wet and dry machining for a multitude of materials and indications

- With touch screen-control

- Leading linear and torque motor technology

Technical specifications

- Number of axes and machining type: 5-axis simultaneous machining

- Max. tilt angle for machining with 98 mm blank: A-axis +/- 30° / B-axis +/- 25°

- Wet processing: Integrated

- Maximum speed / Pmax~: 50,000 rpm / 2.3 kW

- Axle drives: Linear motors and torque motorsabsolute measuring systems, resolution of 0.5 ?m

- Tool fitting: HSK 25

- Tool changer: 32-fold with chip protection cover

- Blank changer: with zero point clamping system / 16-fold fully automatic (loader)

- Weight: 930 kg

- Width x depth x height: 1325 x 1100 x 1940 mm

- Supply voltage / frequency / power: 400 V - 3 phase / 50/60 Hz / 2800 W

- Compressed air supply: 6-9 bar constant supply, 100 liters/minute

- Materials: CoCr/NEM, titanium, zirconium dioxide, aluminum oxide, PMMA, acrylics, composites, wax, glass ceramics, hybrid ceramics

- Compatibility: 98 mm/98.5 mm blanks, CAD/CAM blocks, nt-Trading prefabricated abutments, Medentika PreFace® abutments, Baltic Denture, Lava Frames