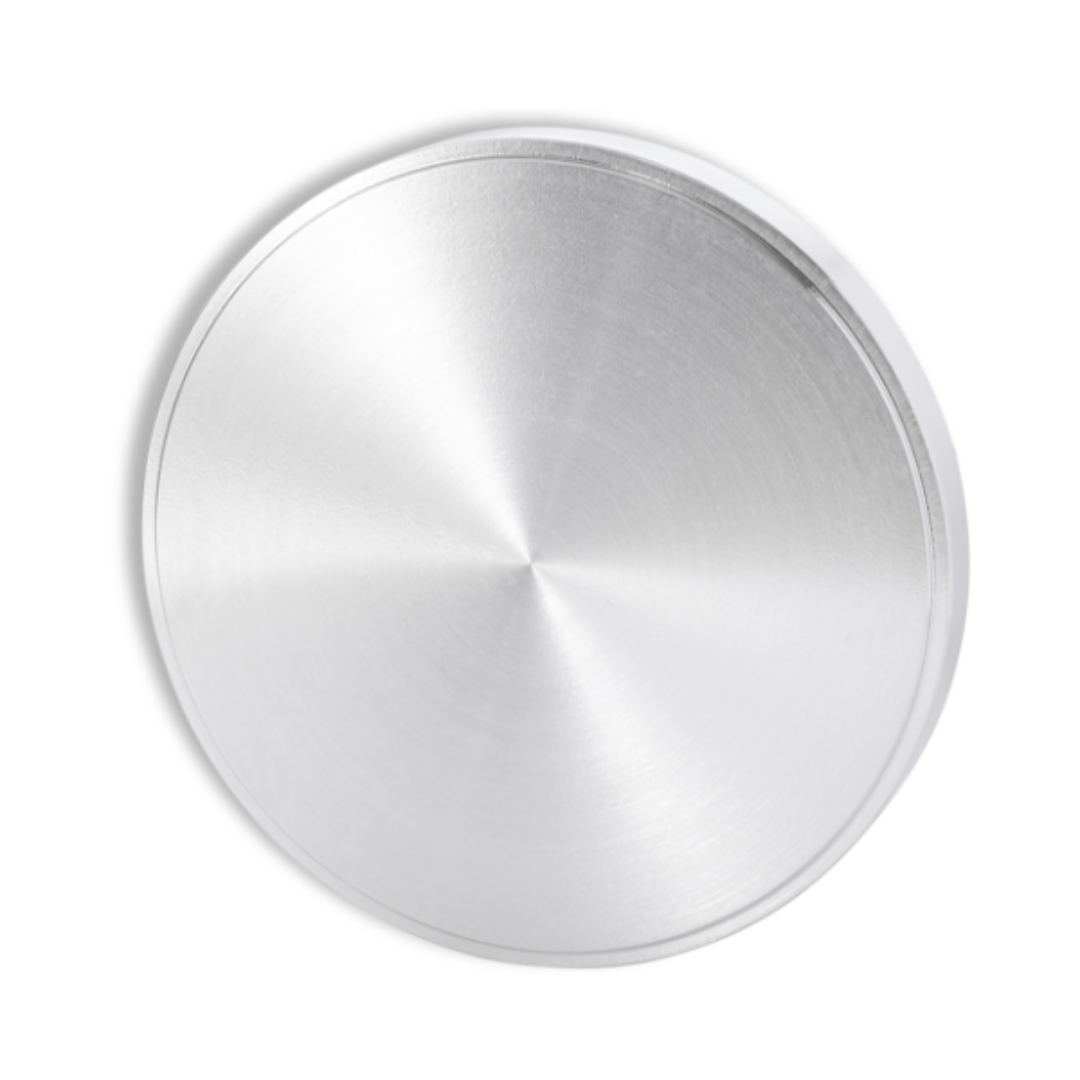

Microlit Isi, 1Kg, CoCr ceramic alloy

Description

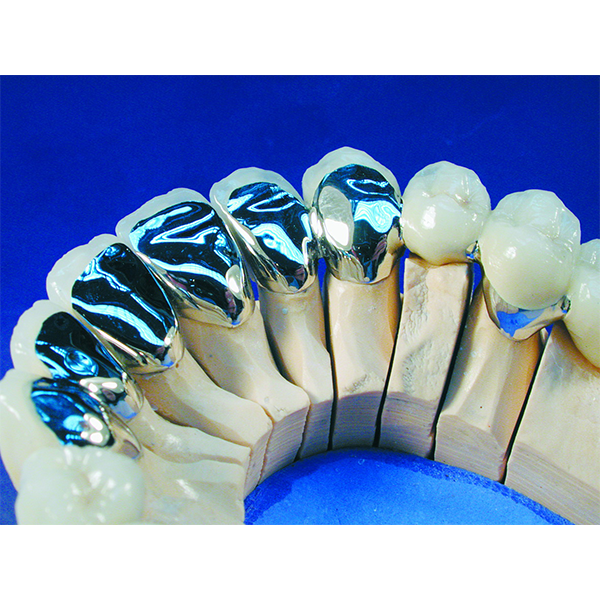

The biocompatible CoCr-alloy for the ceramic facing technique (crowns/bridges). Experience the material's low oxide formation and great polishing behavior.

Product number:

622125

Questions about the product? We are glad to be here for you!

Product information "Microlit Isi, 1Kg, CoCr ceramic alloy"

Microlit isi meets high quality standards

The biocompatible CoCr-based ceramic alloy. An excellent solution for even the most graceful constructions.

Your benefits:

- Simple and quick processing and polishing

- Easy handling, similar to handling a high-precious alloy

- Oxide on full cast objects can be removed easily with a rubber polisher

- Low risk of overheating, the ingots become visibly liquid at the melting point

- Easy to grind, ideal for telescopic restorations

- Smooth and homogeneous surfaces after taking out of the mold

- Light oxide = more aesthetic color of the facing

- Ideal for laser welding

Easy processing, excellent grinding behavior by means of an optimal hardness

- Optimal CTE value, similar to the CTE of a classic ceramic alloy

- Biocompatible, free of nickel and beryllium

- High corrosion resistance

Physical properties:

- Type: 4 (EN ISO 22674)

- Composition (%): Co 61.1/Cr 27.8/W 8.5/Si 1.7

- Melting interval (°C): 1320-1420

- Casting temperature (°C): 1470

- CTE 25 - 600 °C 14.1 x 10-6 K-1

- Vickers hardness (HV 10): 280

Brochures and further information on this product