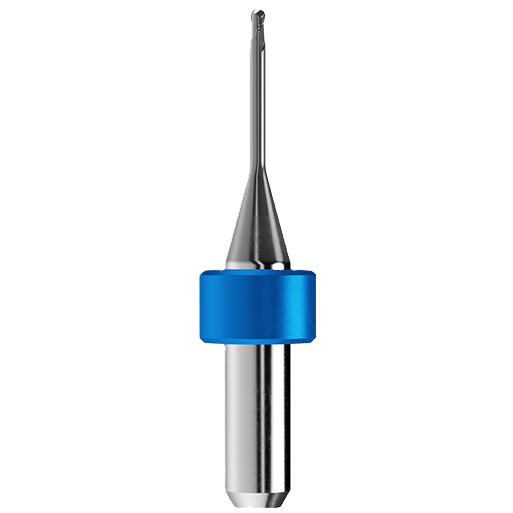

Tizian 3.5 1,5 mm premium flat drill for CoCr/Ti, T5/T10, for 6 mm chuck

Description

T5/T10 Use this robust shaft mill for drilling screw threads and for screw head bearings

Product number:

523986

Questions about the product? We are glad to be here for you!

Product information "Tizian 3.5 1,5 mm premium flat drill for CoCr/Ti, T5/T10, for 6 mm chuck"

T5/T10 shaft mill, double-edged, edge Ø 1.5 mm, shaft Ø 6 mm, max. blank heights = 25 mm.

- Finishing type: drilling screw threads, production of screw bearings

- Blank material: CoCr, titanium

- Coating type: coated

- Ring color gold

- For milling machines: Tizian Cut 5.2, Tizian Cut 5.2 plus, Tizian Cut 5.2 Pro, Tizian Cut 5.2 Pro plus, CORiTEC 550i, CORiTEC 650i

| Beschichtung: | Beschichtet |

|---|---|

| Maschinentyp: | Tizian 3.5/Tizian Cut 5.2 Serie |

| Standard/Premium: | Premium |

| Werkstoff: | NEM/Co-Cr, Titan |