Filter

The item has been added to your inquiry list

Microlit isi,250g,c+b non precious alloy, non-precious ceramic alloy

Variante:

250 g

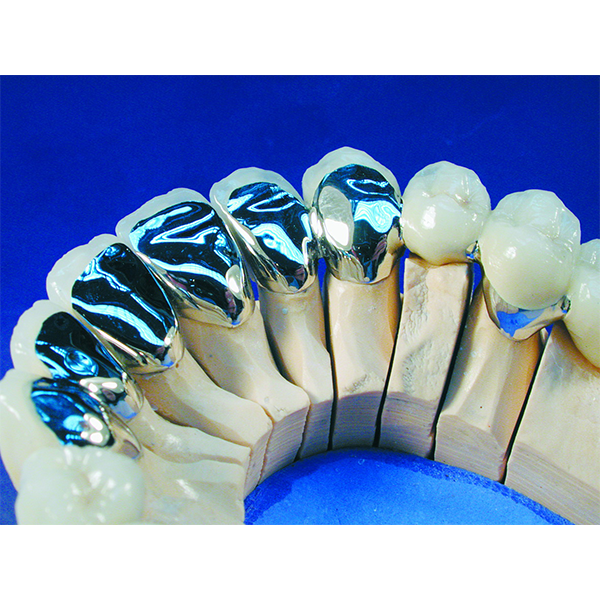

Microlit isi meets high quality standards The biocompatible CoCr-based ceramic alloy. An excellent solution for even the most graceful constructions. Your benefits: Simple and quick processing and polishing Easy handling, similar to handling a high-precious alloy Oxide on full cast objects can be removed easily with a rubber polisher Low risk of overheating, the ingots become visibly liquid at the melting point Easy to grind, ideal for telescopic restorations Smooth and homogeneous surfaces after taking out of the mold Light oxide = more aesthetic color of the facing Ideal for laser welding Easy processing, excellent grinding behavior by means of an optimal hardness Optimal CTE value, similar to the CTE of a classic ceramic alloy Biocompatible, free of nickel and beryllium High corrosion resistance Physical properties: Type: 4 (EN ISO 22674) Composition (%): Co 61.1/Cr 27.8/W 8.5/Si 1.7 Melting interval (°C): 1320-1420 Casting temperature (°C): 1470 CTE 25 - 600 °C 14.1 x 10-6 K-1 Vickers hardness (HV 10): 280

Micronium Exclusiv, 1 kg, CoCrMo alloy

The alloy for your cast attachments, implant supra-constructions and delicate frameworks. Benefits: Extremely hard High elongation at break Easily removed oxide Excellent to polish Extremely bright sheen after polishing For delicate model casting Suitable for large and also delicate construction Physical attributes Hardness: HV 398 Elongation at break: 6% Tensile strength: 980 µPa Specific weight: 8.3 g/cm2 Melting range: 1368-1385 °C Both alloys contain <, 0.5% carbon. They are suitable for lasers and will not become brittle (heat cracks). Both alloys have been tried and tested for more than 25 years. They are biologically safe and bio-compatible. Naturally, neither alloy contains nickel or beryllium or any other contentious ingredients.

Micronium N10, 1 kg, CoCrMo alloy

CoCr alloy specially for your delicate clamp frameworks. , Benefits: Extremely high elongation at break (11%) Extremely high tensile strength (1680 N/mm 2) Easily removed oxide High level of safety and long life span Very high spring stiffness - particularly important for clamps Very good activation , Physical attributes: Hardness: HV 340 Elongation at break: 11 % Tensile strength: 1.680 µPa Specific weight: 8.4 g/cm2 Melting range: 1343-1398 °C

Nicor, 500g, NiCr ceramic alloy

This nickel alloy is characterised by its easy workability and can be veneered using most high melt ceramics. ,

Laser welding wire, CoCr, 0.5 mm round, 0.5 mm round

For safe welding of your CoCr technical dental work using the laser and plasma welding technique.

Laser welding wire, CoCr, 0.35 mm round, 0.35 mm round

For safe welding of your CoCr technical dental work using the laser and plasma welding technique.