Sinter your restorations made from zirconium dioxide with one of these great furnaces. The furnaces are manufactured in Germany with high-quality parts and materials. They will help you sinter your dental restorations safely and to a precise fit. All three Tizian Sintering Furnaces are freely programmable and thus offer you the opportunity to sinter different zirconium dioxide materials.

Filter

The item has been added to your inquiry list

Sinter oven HT-2/M/Zirkon-120,

HT-2 - larger capacity for a higher level of performance With the larger heating chamber, the furnace can process three sintering trays Ø = 120 mm in one conventional long-term sintering process. The heating system with six high-quality molybdenum disilicide heating elements (MoSi2) facilitates SPEED-sintering processes within 76 min. These extraordinary features provide an optimal basis for dental labs and milling centers. HT-2 is operated with a simple, self-explanatory program control. 4-line LCD-display, timer for overnight sintering, drying programs for wet-machined restorations. Three service programs for the maintenance of heating chamber and heating system are available. 90 single crowns or sintering disc Molybdenum disilicide heating elements PRO Max. temperature: 1650 °C Performance max.: 3800 W Capacity of the sintering chamber: 3 x?Ø?120/30 mm Height of the sintering chamber: 102 mm Number of heating elements: 6 Program control (LCD-display, 4 stages, 30 program slots) Service programs A?-?Temperature control* (only in conjunction with test-kit)C - Purge heating chamber E - Regenerate heating elements Thermo couple: PtRh-Pt, type S Temperature accuracy at 1500 °C: +/-3 °C Timer Weight: 74 kg Dimensions W/D/H: 500/560/820 mm

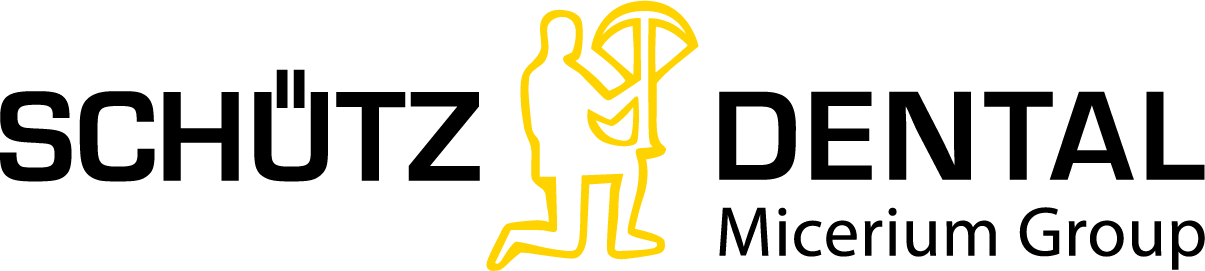

HTS-2/M/ZIRKON- 120, Sinter furnace

Due to a heating system with four high-quality molybdenum heating elements (MoSi2), the user can choose between conventional long-term sintering and SPEED sintering with a heating rate of 99 °C/min.The easy and convenient handling of the program control was adopted from the previous series along with all the familiar functions. The programs are displayed on a 4-line LCD display. Further options are a timer function for sintering over night or the use of drying programs for wet machined restorations. Three service programs for the maintenance of the combustion chamber are available.60 INDIVIDUAL CROWNS OR SINTERING BLANKS Molybdenum disilicide heating elements PRO Capacity of the combustion chamber 2 x?Ø?120/30 mm Program control (LCD-display, 4 levels, 30 program slots, special function) Service programsA?-?temperature control*only in connection with test kitC?- Cleaning of the combustion chamberE?-?Regeneration heating elements Thermo element PtRh-Pt, type S Temperature precision at 1500 °C +/- 3 °C Timer function Technical data Capacity max. 3200 W Max. temperature 1650 °C Voltage range / frequency 200-240 V / 50-60 Hz Weight 60 kg Dimensions w/d/h 390/500/790 mm Number of heating elements: 4 Height of combustion chamber 72 mm Sintering trays 120/30 mm

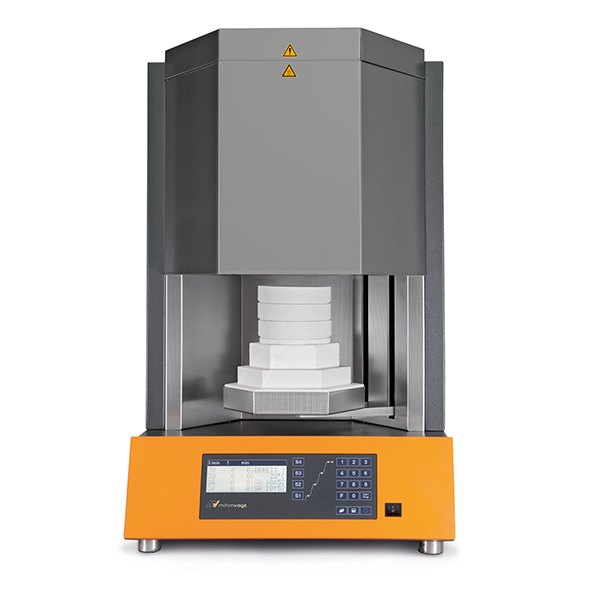

Tizian Furnace 100, Sinter furnace

The Tizian Furnace 100 is ideal for smaller CAD/CAM systems or for supplementing existing sintering furnaces. The respective capacitiy from one sintering tray Ø = 100 mm. Your sintering program can easily be entered and saved in the program controller. Pre-set service programs support you during the simple maintenance and cleaning of the heating systems. Designed for conventional long-term sintering. Heating elements made from molybdenum disilicide facilitate a maximum furnace temperature of 1650 °C. Preset service programs help regenerate contamination of the heating elements. The Tizian Furnace 1002 is equipped with 4 high-quality molybdenum disilicide heating elements of the latest generation which facilitate a sintering temperature of up to 1650 °C. The regular execution of pre-set service programs can prevent possible discoloration of restorations and increase the life span of the heating elements and the heating chamber. molybdenum disilicide heating elements Maximum temperature: 1650 °C Performance: max. 1500 W Voltage range / frequency 220-240 V / 50-60 Hz Number of heating elements: 4 Height of the sintering chamber: 42 cm Service programs A?-?Temperature control* (only in conjunction with test-kit)C - Purge heating chamber E- Regenerate heating elements Program control (7-Segment LED, 4 stages, 9 program slots, special features) Thermo couple PtRh-Pt, type S Maximum heating rate 25 °C/min. Temperature accuracy at 1500 °C +/- 3 °C Timer Weight: 55 kg Dimensions W/D/H 400/400/600 mm

Sintering cup speed, 120/30 slitted, for sinter oven HT-2/M/Zirkon-120

Sintering tray for the sintering furnace HT-2/M/Zirkon-120. 120/30 mm slotted